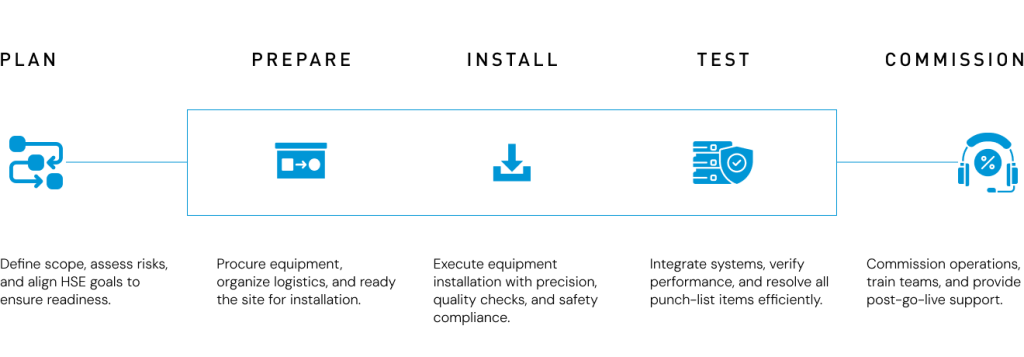

Every commissioning is an engineering commitment. We install, test, and hand over assets that meet safety, technical, and performance benchmarks – ensuring right-first-time start-ups across various industries.

Installation and commissioning demand discipline, documentation, and deep process understanding. We combine project management rigor with field execution so every system – mechanical, electrical, or digital, is installed and verified exactly as designed.

From pre-installation planning through handover, our teams follow safety-led methods, structured testing, and transparent reporting, so day one performance is reliable, compliant, and repeatable.

Industries

Supervision and commissioning of rotating equipment, HVAC, switchgear, PLCs, and instrumentation to OEM and safety standards.

Installation/validation of chillers, compressed air, water treatment, and utility networks for reliable plant services.

Testing and configuration of SCADA, PLC, and DCS systems for digital reliability, cyber compliance, and real-time performance.

End-to-end setup of solar and hybrid power systems, ensuring safe synchronisation and efficiency from first start.

Protocol-driven commissioning for pharma/biotech/food facilities with calibration, air validation, and full GMP documentation.

Installation and handover of intelligent building systems, transport, and vertical mobility with integrated safety and automation.

Our cross-sector experience keeps India’s core industries moving – from metals and power to pharma and urban infrastructure.

Mechanical and electrical commissioning of vertical mobility systems - elevators, escalators, and moving walks - delivered under strict safety and quality standards.

End-to-end installation and commissioning of solar and hybrid energy projects, ensuring performance, safety, and timely synchronisation to the grid.

Commissioning and integration of smart metering systems, control panels, and communication networks that improve grid reliability and transparency.

Structured methodology, OEM-aligned procedures, and safety-first execution. We back every activity with documented tests and clear acceptance criteria.

Yes, from equipment-level assistance to turnkey plant commissioning under AMC.

ISO-aligned checklists, hazard controls, calibrated instruments, and third-party/ client-witnessed tests ensure regulatory and OEM compliance.

Absolutely. We validate SCADA/DCS/PLC logic, cybersecurity prerequisites, and integrate with CMMS/EAM for traceable handover.

As-built documentation, test certificates, O&M manuals, training, spares lists, punch-list closure, and formal acceptance sign-off.